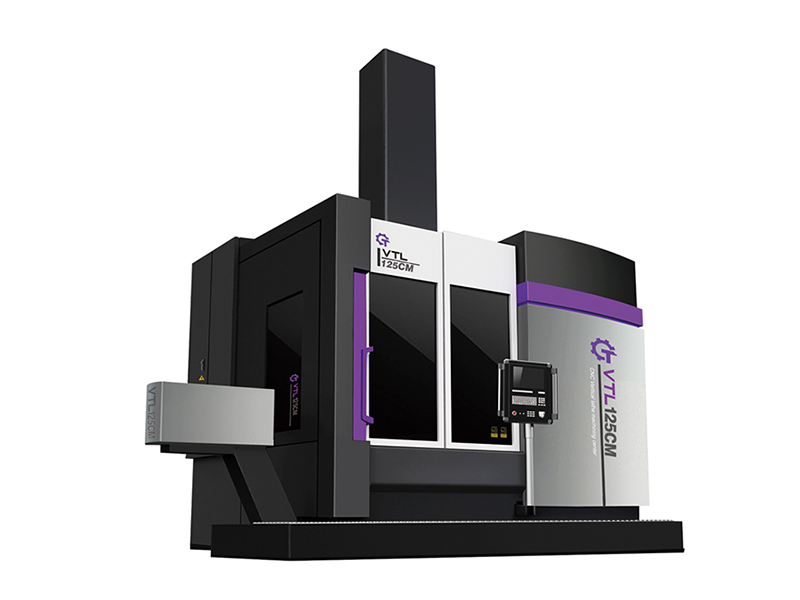

CNC Vertical Lathe

VTL-CM vertical turning and milling center series, that is double column vertical turning and milling machine with movable beam, developed and designed by our company according to market demand,that we make use of key process technology, proceed new design of lathe machine structure, do technological process research and the commissioning work of lathe.

Product Details

Technical Parameters

● VTL-CM vertical turning and milling center series, that is double column vertical turning and milling machine with movable beam, developed and designed by our company according to market demand,that we make use of key process technology, proceed new design of lathe machine structure, do technological process research and the commissioning work of lathe. It adopts the structure of full protection of host machine and centralized layout of mechanical, electrical and hydraulic parts integrated for the machine.It mainly consists of lathe frame, tool holder movement in X-axis direction and Z-axis direction, worktable rotation around C-axis, B-axis of milling, control board, automatic filings removal, temperature control device, automatic lubricating part, hydraulic system, tool changer, safety protection, electronic control system and electric cabinet etc.

● It takes the products from famous manufacturers in domestic and abroad for key parts, such as CNC system, key electrical components, key bearings, ball screws, key hydraulic parts etc..

● With importing of mature technology and usage of imported reliable parts, as well as our advanced processing and test methods, that ensures the machine has high accuracy of machining, high rigidity and high reliability. Besides,it has the features of reasonable layout, easy operation and high automation. It can realize automatic tool change, automatic machining, improve machining quality and reduce operation cost.

● The lathe machine is suitable for machining large parts in the industries of power generation, shipbuilding, metallurgy, mining etc..

| Specification | Unit | VTL160CM | VTL200CM | VTL250CM | |

| Processing capacity | Work table diameter | mm | 1400 | 1600 | 2000 |

| Max. swing diameter | mm | 1600 | 2000 | 2500 | |

| Max. turning diameter | mm | 1600 | 2000 | 2500 | |

| Max height of workpiece | mm | 1200 | 1200 | 2000 | |

| Max. weiqht of workpiece | kg | 5000 | 8000 | 12000 | |

| Max torque of work table | N.m | 17500 | 25000 | 28000 | |

| Accuracy | Machining accuracy | IT6-IT7 | IT6-IT7 | IT6-IT7 | |

| X/Z positioning accuracy | mm | 0.018/0.020 | 0.018/0.020 | 0.018/0.020 | |

| X/Z repeat positioning accuracy | mm | 0.008/0.01 | 0.008/0.01 | 0.01/0.01 | |

| C-axis positioning accuracy | sec | ±3" | ±3" | ±3" | |

| C-axis repeat positioning accuracy | sec | 3" | 3" | 3” | |

| Turning spindle | Spindle speed range | r/min | 1-300 | 1-250 | 1-200 |

| Speed shift of worktable | Stepless ( two speed shifts) | Stepless ( two speed shifts) | Stepless ( two speed shifts) | ||

| C axis speed | rpm | 0.01-7.0 | 0.01-6.0 | 0.01-5.0 | |

| Main motor output power | 30 mins rated | kW | 30 | 45 | 55 |

| Continuous rated | kW | 26 | 37 | 45 | |

| Tuminq max. cuttinq force | kN | 25 | 25 | 30 | |

| Milling shaft | Max. speed | rpm | 2250 | 2250 | 2250 |

| Motor power | kW | AC11/15 | AC11/15 | AC11/15 | |

| Ram | Ram section size | mm | 220X220 | 250X250 | 250X250 |

| X axis travel | mm | -200 - +950 | -200-+1150 | -200 - +2000 | |

| Z axis travel | mm | 900 | 900 | 1200 | |

| Feeding speed | Cutting feeding speed | mm/rev | 0.01-50 | 0.01-50 | 0.01-50 |

| Rapid feeding speed | mm/min | 8000 | 8000 | 8000 | |

| Beam travel | mm | 800 | 800 | 1000 | |

| Beam lifting gear distance | mm | 4x200 | 4x200 | 4x250 | |

| ATC Tool changer | Tool capacity | 16 | 16 | 16 | |

| Turning tool bar size | mm | 32x32 | 32x32 | 40x40 | |

| Total power | Voltage | V | AC380 | AC380 | AC380 |

| Voltage wave range | -10~ +10 | -10~ +10 | -10~ +10 | ||

| Frequency | Hz | 50 | 50 | 50 | |

| Total power | kW | 68 | 75 | 95 | |

| System | CNC device model | SIEMENS840DsL | SIEMENS840DsL | SIEMENS840DsL | |

| Machine weiqht | kg | 25100 | 28200 | 49000 | |

| Overall dimension of machine(LxWxH) | mm | 7000x4900x5600 | 7500x5300x5800 | 7800x6500x7350 | |

About Us

Products

Service

Our major products: Single column CNC vertical turning lathe, double column CNC vertical turning lathe, horizontal boring and milling machine series. In terms of development and innovation, especially the series of vertical turning lathe through the certification of home and abroad expert. Our products realize the industry leading level, it brings the higher recognition and honor in the market.